This article asks: why your facility needs thermal surveys? Learn how thermal imaging technology can safeguard your facility's infrastructure, improve safety standards, and ensure regulatory compliance.

Safe and Fast

Thermal surveys are becoming increasingly popular for building maintenance due to their efficiency and safety. Also known as thermographic or thermal imaging surveys, they serve as a revolutionary alternative to traditional maintenance methods. One of the key advantages of thermal surveys is that they promote safety and efficiency. In contrast to conventional procedures, these thermal inspections do not necessitate any physical interaction any equipment or surface and requires no access equipment, thereby limiting the possibility of injuries or damage.

Moreover, thermal surveys enable swift scanning of large-scale areas, offering a plethora of vital data upon which immediate actions can be taken. Those responsible for facility maintenance highly value speed, and a thermal survey certainly does not disappoint in this regard. This expedited method allows for a thorough inspection to be conducted without hampering operations, making it a cost-effective alternative.

This is particularly beneficial in the realm of facility management, where time equates to money. In other words, the speediness of a thermal survey is a standout feature, providing significant time and cost savings. When compared to the traditional approach, the rapidity and safety aspects of these innovative surveys clearly underscore their increasing popularity and prominence in building management and maintenance.

Fault Diagnosis

Another key aspect that should encourage your facility to utilise thermal surveys is its notable ability to detect and diagnose faults. These surveys provide a much deeper level of investigation than typically available.

With the inclusion of thermal imaging technology, you have the power to uncover and diagnose hidden issues that might easily be missed by the human eye, such as faulty insulation, overheating components, and potential hazards that pose a risk to your operation.

Equipment malfunctions and failure can lead to severe consequences, including business disruption and unexpected expenditure. By using thermal surveys, you have the ability to proactively identify these issues at their earliest stage.

When issues are diagnosed promptly, they can usually be addressed before they escalate and trigger more serious, potentially disruptive problems. Thermal surveys are designed to detect irregularities in heat distribution across your facility's equipment and physical infrastructure.

This substantial capability goes a long way in helping to prevent the occurrence of minor faults from becoming major, costly disturbances to your operations. By identifying hot spots within your systems, opportunities present themselves to intervene in a minor issue before it becomes a serious problem.

These surveys are especially critical for organisations that utilise complex electronic systems, which can produce considerably high heat levels. The likelihood of minor issues escalating into bigger problems increases under such conditions. Furthermore, by detecting these issues early, facilities can prevent damage to equipment, prolong their lifespan and maintain optimal operation.

This, in turn, eliminates potential downtime and the associated cost implications. In conclusion, thermal surveys are an invaluable tool for any facility. Their ability to detect and diagnose issues beyond the reach of the naked eye, and before they escalate into more significant problems, makes them essential preventive measures. So, if you are searching for ways to improve efficiency and maintain the health of your equipment and building, thermal surveys should be high on your list of considerations.

Avoid Downtime

Downtime is an unwelcome enemy of productivity and efficiency. For any professional facility, avoiding downtime is an extremely important objective. It's essential to fulfilling productivity targets and keeping the business running smoothly. Without a doubt, the financial burdens that come with stopping operations due to equipment malfunctions or building defects can be quite heavy. Additionally, the negative impact on your operations may have wide-reaching and enduring effects.

Against this backdrop, the undeniable benefits of regular thermal surveys become strikingly noticeable. These modern technological tools offer an efficient method of detecting problems before they escalate. With real-time data and accurate digital reports from these thermal imaging surveys, you obtain the capability to proactively identify and address potential issues before they grow into something worse, leading to a complete shutdown of operations. This preventative approach ensures that your operations continue to run seamlessly, preventing unnecessary interruptions to your work.

Furthermore, the fast nature of thermal surveys means that you can obtain this invaluable data without needing to briefly suspend your regular operations. This seamless mixing into your normal operations comes with the added benefit of not interrupting the workflow, thus guaranteeing a steady maintenance routine. This way, you can keep your operations running smoothly, saving time, energy and resources. In doing so, your business can remain efficient, productive, and ultimately, successful.

Identifies a Range of Issues

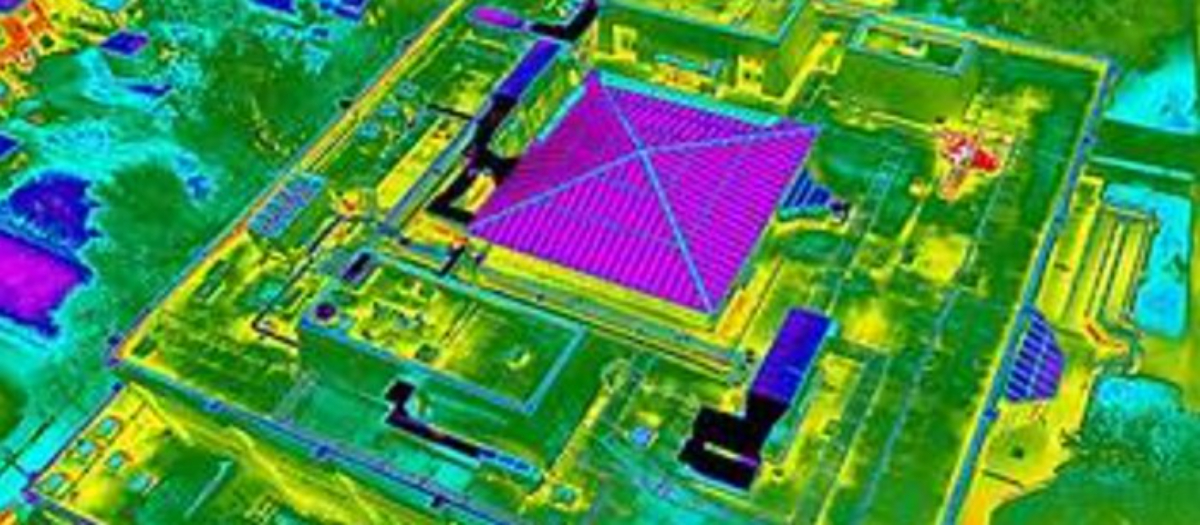

Last, but certainly not least, thermal surveys can pinpoint a broad array of problems within your facility. Everything from inefficiencies in your heating, ventilation and air conditioning (HVAC) system to defects in your roofing can be detected.

In addition, any abnormalities in your electrical setup or gaps in your insulation can also be caught through these meticulous examinations. Thermal imaging is incredibly versatile, making it a priceless asset for any facility's maintenance toolkit.

The ability to detect an abundant range of issues in one sweeping scan underlines the strength and utility of thermal surveys. They give you the invaluable opportunity to swiftly address and rectify these problems, thus preventing any further damage and minimising potential losses.

Increasing the efficiency of your HVAC system can greatly lower your energy consumption, resulting in a significant decrease in utility costs. Detecting defects in your roof early can prevent costly water damage repairs down the line.

Meanwhile, identifying electrical abnormalities can potentially save you from expensive electrical fires. Lastly, finding insulation gaps and rectifying them in a timely manner can ensure that your facility's interior temperature remains steady, leading to further savings on heating and cooling costs. The power of thermal surveys goes beyond simple cost savings. By identifying and rectifying problems early, you protect your facility from long-term damage that can affect the overall lifespan of your building.

Moreover, a well-maintained facility goes a long way in maintaining high morale among your employees and delivering a positive impression to clients or customers visiting your premises.

In essence, thermal surveys play a crucial role in every aspect of your facility's maintenance strategy. They provide comprehensive insights into every nook and cranny of your building, revealing issues that might otherwise go unnoticed until they escalate into more serious, and expensive, problems. So, do not underestimate the value and far-reaching effects of thermal surveys. Invest in regular examinations to keep your facility in optimal condition. By doing so, you're not just saving money or preventing damage— you're also investing in the future of your facility, and by extension, the future of your company.

Fantastic Results

It's indisputable that thermal surveys deliver remarkable results. Incorporating them into your regular facility upkeep regimen can generate extremely beneficial outcomes. Firstly, the accuracy of thermal imaging is unrivalled. Whether it's used to identify heat loss within the building or to spot leaks in defective flat-roof membranes, the precision of thermal surveys is particularly remarkable. One of the foremost advantages of thermal imaging is its ability to pinpoint issues without causing any disruption to the operation of your facility.

Traditionally, the inspection of building components and/or machinery can be disruptive and potentially damaging, but this is not the case with thermal surveys. Their non-intrusive nature significantly reduces the risk of equipment damage during inspections, thereby saving unnecessary expenditure on repairs and replacements.

Furthermore, the detailed and extensive analysis provided by thermal surveys aids in devising effective maintenance strategies. They deliver extensive data and valuable insights that can guide decision-making. This data can help you identify problem areas that require immediate attention, forecast potential issues and thus prepare in advance.

This targeted approach to maintenance and repairs ensures your investment in thermal imaging is well justified. So, if you're considering whether to integrate thermal surveys into your maintenance routine, the multiple benefits they offer make it a decision well worth considering. Yield excellent results, reduce the risk of equipment damage, and make targeted repairs with this efficient method of survey.

At Dog House Drones, we provide survey and inspection services across Milton Keynes, Buckinghamshire, and the surrounding counties. We offer a range of services with a customer focused approach and an ethos of preventative maintenance that will deliver cost-savings, minimised disruption, and a vastly reduced carbon footprint to our customers. We’re fully qualified, efficient, trustworthy, and have the expertise to provide the exact services that our customer’s require.